Processing

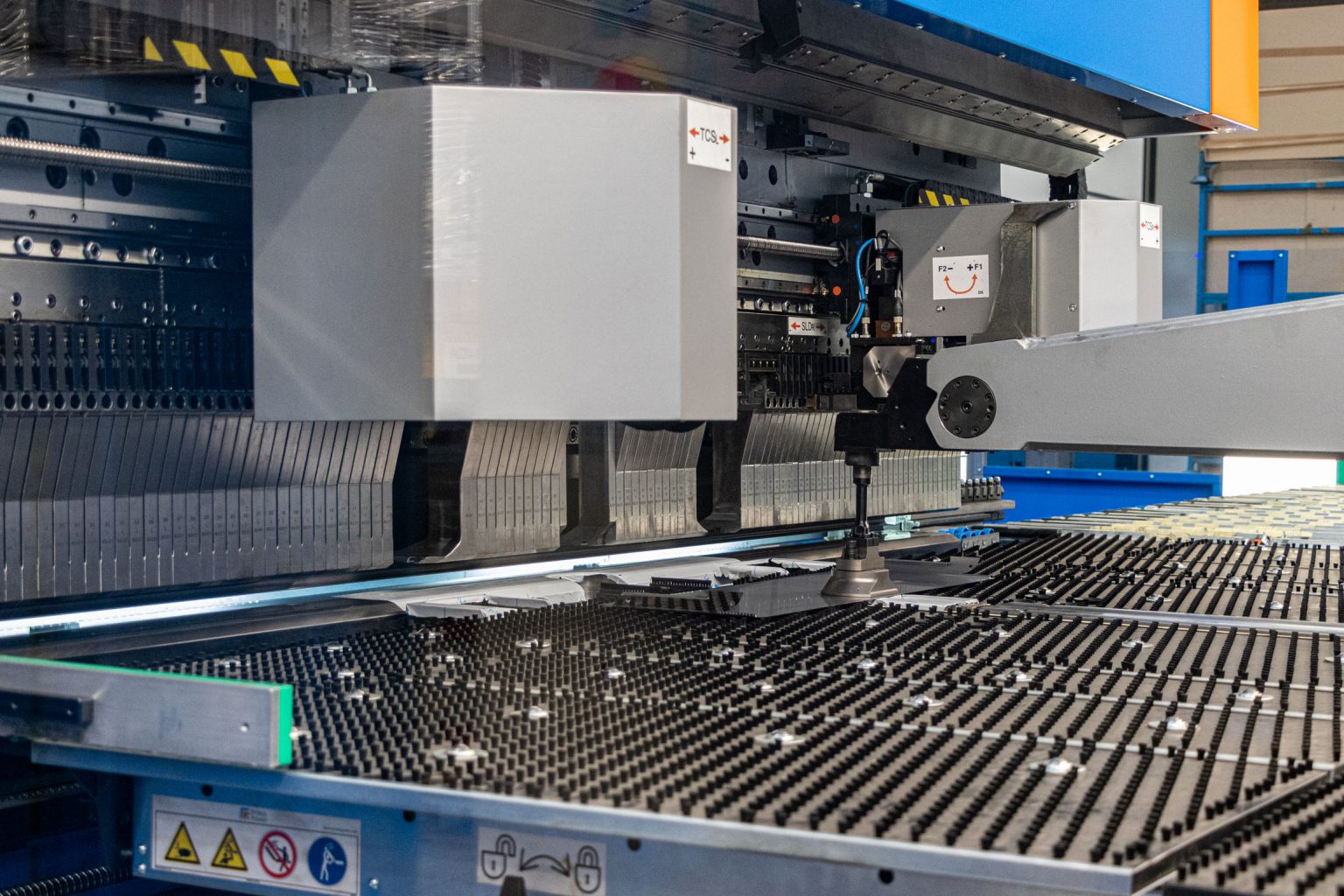

Steel Bending / Panelling

Steel bending is the stage immediately following laser cutting. This is where the product really begins to take shape, be it the final or intermediate stage that precedes further processing such as welding, assembly, painting, screen printing, etc.

Our constantly evolving department consists of a fleet of 7-axis CNC bending machines, which provide a working range of up to 3 metres with a force from 50 tons to 165 tons and allow us to process sheet metal in any shape required by the project, even the most complex ones for multiple industrial applications such as catering, refrigeration, furniture and lighting components and medical.

Industry specialists

The high level of specialisation of our bending department guarantees optimised industrialisation and mass production of the designed elements using management software and accurate production planning to reduce delivery times.

Recently, the department was expanded with the new TruBend Center 5030 technology, which has been adapted to be able to produce a range of parts never before achieved with machines of this type, and with the aim of automating the workflow.

The latest addition is the BCe 2720 Prima Power® panelling centre with automatic workpiece handling, which allows increased productivity while maintaining and improving the quality of the parts obtained.

Thanks to the many years of experience and expertise of Rizzato’s in-house technical department and thanks to advanced and diversified technologies, in our bending department can be processed quickly and flexibly even complex components, far exceeding the range of parts made with conventional bending technology. From door frames to tubs with high bending edges, it is possible to create components for various applications in different industries.

The machines that make up the department:

– FBE 5 Fast Bend Prima Power® panelling machine

– Excellent bending quality thanks to angle correction database and servo technology

– Perfect for bending various types of parts.

– Prima Power’s Fast Bend is an intermediate product between the traditional press brake and the automatic panel bender. It allows multiple folds on each side to be made in automatic sequence, including positive/negative inversion, flattened and radius folds. Only loading, turning and unloading operations are manual.

– BCe 2720 Prima Power® paneller with automatic handling

– Excellent fold quality thanks to angle correction database and servo electric technology.

– Equipped with two safety light curtains that monitor the loading and unloading area, ensuring safe operation

– Automatic handling enables faster and more consistent processing times

– Two Trumpf Trubend Center 5030 panelisers

– Semi-automatic panelising machine, produces a range of parts never before achieved with machines of this type.

– The 2-axis manipulator positions the sheet metal and also enables negative bending.

– Only the loading, turning and unloading operations are manual.

– CNC press-benders from 2m to 3m (50 Ton x 2m to 165 Ton x 3m) – Gasparini

– 8-axis CNC press brake 3m (from 100 Ton) – Gasparini